A hot runner system is an assembly of heated components—hot halves, nozzles and gates and—that inject plastic into the cavities of an injection mold. The system usually includes a heated manifold and a number of heated nozzles. The manifold distributes the plastic entering the mold to the nozzles, which then meter it precisely to the injection points in the cavities. The hot runner is equipped with its own temperature control system.

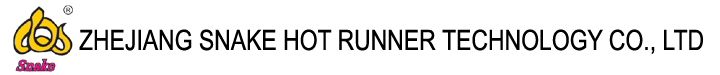

- PSZ

PSZ type hot nozzle, suitable for all kinds of plastic, it shows point shape when entering the gate, with height of 0.2-0.8mm, easy to change the color, enhance the beauty of the product.

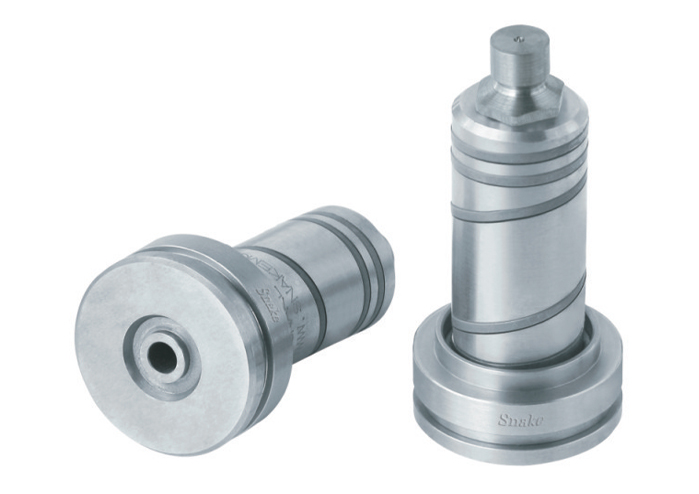

- DPSZ

DPSZ type hot nozzle, suitable for all kinds of product, it shows point shape when entering the gate, there is a circle on the surface of the product, easy to change the color.

- PZ

PZ type hot nozzle, suitable for all kinds of plastic, the gate of the nozzle has material handle, which is of 10mm length. Lengthen gate is of 30mm length, which can process the slope freely according ...

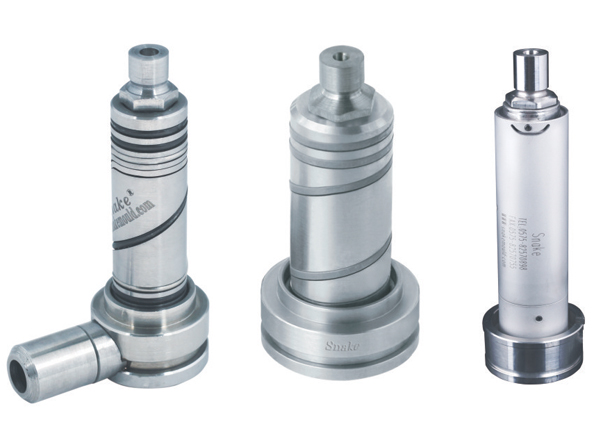

- PSZT

PSZT type hot nozzle ,suitable for plastic product with small scale but with good fluidity , which can produce one product in one nozzle ,also suitable for the multi-products in one nozzle .

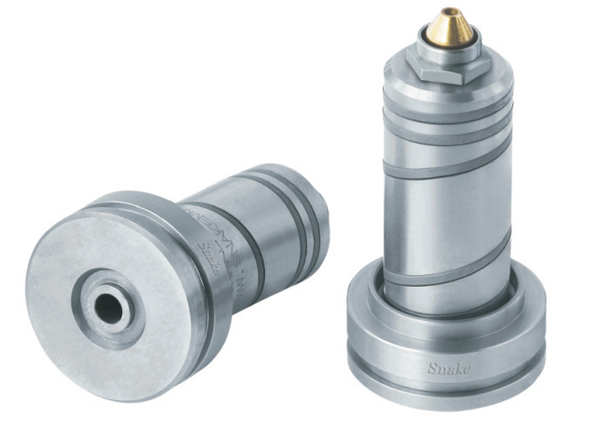

- PSZZ

PSZZ type hot nozzle,suitable for all kinds of plastic, the gate of the product has a material handle which is of 3-4mm height and Φ4 diameter, and between PSZ and PZ.

- FPSZZ

FPSZZ Valve type hot nozzle ,suitable for all kings of plastic ,the gate for the product is a small circle ,usually it is a concave surface of 0.3mm ,the gate is very beautiful.